Hanwei lugu

Katana konstruktsioon

Hanwei mõõkade terastest

Katanade võrdlus

|

Monosteel Katana

Construction

|

| This is a quick

outline of the many steps involved in creating a high quality monosteel

(non-folded) Katana. |

Blade Construction:

|

|

1. Rough Forging: The blade is

formed by hot forging a billet of

high-carbon steel. The repeated hammering provides an even dispersion

of carbon throughout the steel for uniform strength of the finished

blade. |

|

2. Rough Shaping: The scale is

removed and the blade is shaped roughly

to the required dimensions. At this stage, the steel is still in the

annealed (soft) state and the blade is straight. |

|

3. Clay Covering: A special

clay is applied to the blade by hand, using

a thin covering near the edge and a thicker layer over the rest of the

blade. This results in a relatively quicker cooling of the edge during

quenching, producing a hard edge and softer back. |

|

4. Quenching: This is a

critical part of the operation. The blade, with

its clay covering, is heated to a predetermined temperature and

quenched in a water bath. The shape and continuity of the hamon, the

sori (blade curvature), and blade straightness are all determined by

the care and skill exercised in quenching. |

|

5. Sizing: The sori is

adjusted if necessary, to set the point of

balance and point of percussion, and the blade is de-scaled. Rough

polishing is carried out to size the blade accurately. The habaki

(blade collar) is fitted. |

|

6. Finishing: Careful final

polishing and fine finish work are carried

out on the various surfaces to define ridgelines and bring out the

beauty of the hamon. |

Furniture Construction:

|

|

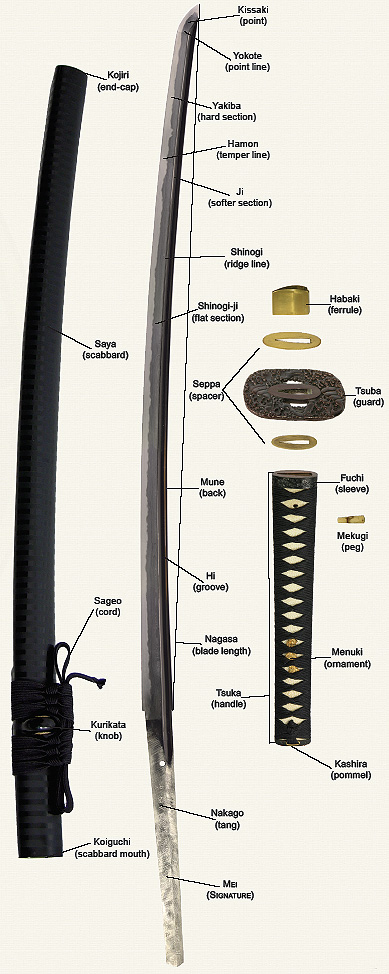

Saya: The saya is carved from

two pieces of wood to match the length,

width, thickness and curvature of the finished blade. The two halves

are then wrapped in cambric and lacquered numerous times. Final

polishing gives the saya finish a high gloss. |

|

Tsuka: The handle core is

comprised of two pieces of hardwood carved to

tightly fit onto the tang. Channels are carved into the sides to

facilitate the fitting of two panels of ray skin. The entire handle is

then wrapped with high quality woven cotton or silk, depending on the

sword being fitted, while small paper triangles are used to help shape

the wrap correctly. The Menuki and Kashira are added during this

process. |

|

Sageo: The sageo is typically

woven of high quality cotton or silk to

match the handle wrap. In some cases, the sageo is still woven by hand

(see Paper Crane). This process requires many hours of skilled hand

labor but allows thematic designs to be worked into the sageo. |

|

Assembly: Finally all the

pieces can be assembled and the handle

securely fastened to the tang. This is accomplished by drilling the

handle and the tang together in two places and inserting bamboo pegs

(mekugi) to pin the handle to the tang. |

The Parts of a Katana:

|

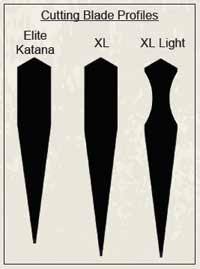

Performance Series Katana

Our Performance Series Katana are the culmination of years of study,

trial, and error into the optimum blade designs for today’s martial

artists. Four distinct variations are available, each optimized for a

particular discipline or cutting application. The Iaito is an unedged

training blade, available in three different lengths, for use in

drawing practice and Kata. Its correctly-weighted and balanced steel

blade prepares the student for advanced work with live blades. The

blade geometry and physical characteristics of each of the Tameshigiri

(cutting practice) blades are tailored towards different targets. The

Elite Katana’s blade is a little wider and a little thicker than its

traditional counterpart, allowing for easier cuts on normal targets,

while that of the Katana XL is significantly wider , for use in cutting

heavy targets. The Katana XL Light has the XL’s profile but is provided

with Bo-hi, reducing the weight to the point where double cuts are

possible but clean cuts on heavier targets may still be made.

|

|

|

|

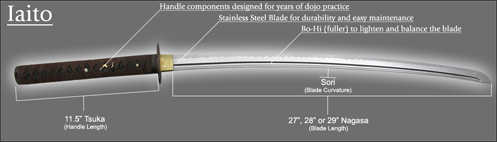

Iaito: Frequent

Drawing Practice

-

These unedged training blades provide for safe drawing for the

beginning practitioner of the 450 year old art of Iaido. Forged from

stainless steel the tempered blades are not only maintenance-free but

more importantly provide the correct weight and balance needed for the

rigors of repetitve drawing and sword motion practice. Each blade has a

deeply cut groove (bo-hi) to provide audible feedback when swung

properly.

|

|

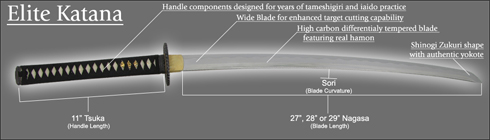

Elite Katana: Frequent

Cutting / Advanced Drawing Practice

-

Our Katana Blades embody the classical design elements of the most

prolific sword design in history. With their strong Shinogi Zukuri

shape that accentuates the differential heat treatment, these blades

are traditionally proportioned to appeal to the collector but they will

also perform well in general cutting of hard or soft targets.

|

|

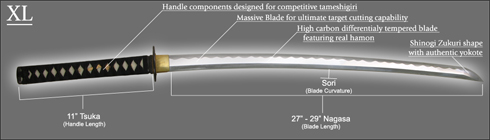

XL: Heavy

Competitive Cutting

-

Designed strictly for competitive cutting, our XL Katana blades

incorporate the geometry, strength, weight and profile needed for

successful cuts on substantial targets. Featuring differential heat

treatment and a narrow edge angle, these wide blades will reward good

technique with clean cuts and excellent durability.

|

|

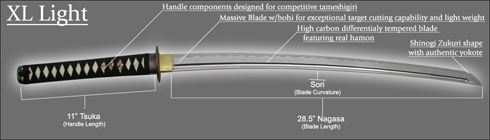

XL Light: Competitive

Cutting / Light Weight

-

The XL Light blades feature the same geometry as those of the XL but

incorporate deeply cut grooves (bo-hi) to reduce the weight of the

blade while retaining most of it’s strength and cutting ability. This

weight reduction makes for a quicker sword, well adapted for multiple

cuts in lighter targets. |

|

|