|

PRODUCT

PROCESSING

All processes are demanded to

numerical control machinery, but every single piece receives a

peculiar handcrafted care

in the finishing process, mechanical adjustments and, most of all,

regarding the sharping which is thoroughly performed by hand.

The choice in materials is the best among what the market offers, which

contributes in giving high performance to our products.

Our products are not art pieces, they're simple and efficient

professional technical instruments.

Our

production

Extrema Ratio produces tactical

knives, that is fixed blade or openable knives for severe use.

The use of special steels, of polymers like KRATON and of processes

like vacuum hardening, make our knives the best cutting instruments.

Care in details, like stainless steels screws, detachable handles,

technical scabbards equipped with belts and extensions make these

instruments the top. This quality results in the adoption of these

instruments by important operative army units.

Potentiality

As

said, Extrema Ratio is a mechanical workshop, therefore we can

virtually face the production of mechanical and plastic instruments.

We have chosen to take in charge the production of tactic knives but

the white weapons license of production and the techical qualification

for the production of common and war weapons held by the two partners

open unlimited horizons in the blade production field. We can thus

produce double edged blades, bayonets, automatic knives and swords.

The

present working area enables us to face production orders both of bulk

quantities and of small amounts (50-100 pieces), upon request from

military units.

CHARACTERISTICS

& MATERIALS

The blades

At present our blades are produced using only N690, a steel martensitic

enriched with chrome, vanadium, molibdene and cobalt, from the finest

homogeneity it is transformed in plate for a crossed lamination/rolling.

Naturally we make the most of nearly ten years experience of using this

steel, it is treated with all the expedients and processes which give

it the maximum in quality. Cutting by high power laser, vacuum thermo

treatment, special sand blasting.

It is protected through burnishing and carbonitruration which can

satisfy the most demanding military specifications. For our entire

production, both military and civilian. This Austrian stainless steel

has resulted in an outstanding combination of strength and flexibility.

All this comes at a very accessible price.

Our ambition is not the perfect blade; our target is to offer our

military customers a functional and efficient blade for a wide range of

uses. With this kind of steel we are rewriting the European military

standards regarding blades. Furthermore all our blades are hand

sharpened, in order to obtain a tough, enduring and efficient

sharpness, which is substantially different to that obtained by

industrial methods.

Handles

for fixed blades

In collaboration with the faculty of Motor Sciences at Perugia

University we have developed the ERMH. This handle lends itself

superbly for both work and combat.

The grip is formed in a hollow which thins the handle and furnishes a

firm grasp for the three stronger fingers of the hand (which make up

the opposing force ).

The handle is asymmetric but straight, which allows for

a dynamic shift from "saber" to "reverse" while leaving the end of the

tang free as a rope guide or for use as a blunt instrument. It is

suitable for hands of all normal dimensions, male or female, and for

use with thermal gloves.

It is a single piece, easy to dismantle, allowing for excellent

ordinary or extraordinary maintenance.

It is produced through a "Forprene" injection, a polymer with extreme

temperature resistance (-40 / +120), thus reaching the requirements for

NATO standards.

Some models, such as the "back up", use the same handle in "ERMH C",

which is more compact, more useful for dissimulation and with low risk

of entanglement: the minimum requirement for a firm grasp.

Fixed blade sheaths

Particular attention has been paid to the development of sheaths which

are, like the handle, the interconnection between the blade and the

user.

The fixed blade and bayonet sheaths have two retaining systems, both of

which can be used ambidextrously.

The first is located inside the hard part of the sheath, it is a

pressure mechanism to avoid losing the knife in case of rolling or

being overturned, the second is a lace with two buttons to fix the

blade handle close to the body, this prevents it becoming entangled

with vegetation, with other equipment (like the rifle sling) or - in

the case of parachuting - with the static line or parachute cord.

It can be carried comfortably and silently.

Its insertion is facilitated by a wide safety opening giving easy

access for replacing the knife when the user cannot see the sheath due

to it being covered by equipment or other gear such as an ammo pouch.

The hard sheath prevents the misplacement of the blade

in case of shock, and aids fast drying, thanks to a drainage hole,

reducing exposure to elements that favour the oxidation process.

The soft part of the sheath is provided with several

points for connection with equipment, an extension and two thigh straps

with elastic and Velcro fixings are included with the sheath. Many of

the sheaths are provided with a fixing system compatible with "spring"

systems.

The straps and all the accessories are in nylon, all buttons

and metallic parts are made from burnished brass or have a polymer

cover.

The semi-rigid sheaths, like those of the bayonets or the KS,

KL, KH, are made in nylon or Cord mixed with closed cell polymeric

sponge that does not absorb humidity and water.

Folding Knives

For

the handle we use Anticorodal, an aluminium alloy with superior

mechanical characteristics and a remarkable resistance to oxidization.

The Anticorodal pieces are burnished through a high level of anodized

oxidation.

The metal parts are made from N690 (like the blade) when a high level

of hardness is required, AISI 304 e AISI 303 where high resistance

against oxidation is needed (screws, pivots, turnings).

Steel parts are burnished either through carbonitrading (with

zirconium) or according to military specifications.

The springs are made in stainless steel burnished with the same

procedures.

The ergonomics of the sheath follow the same standards of the fixed

blade knife, however in this case the lowered surface on the handles

makes the thumb-stud reaching simpler.

Most of the folding knives are provided with a glass

shattering nodule, or in the case of folding knives for heavy work,

they have a protuberance in tempered steel which is attached to the

back of the sheath.

We use only tested blade blocking systems such as "back lock" or "liner

lock".

TEST

To obtain the development of

products with a high level of performance, our prototypes and samples undergo

the strictest NATO tests, integrated with other more specific

and even stricter tests carried out inside our laboratory.

To ensure a real and absolute

efficiency, we execute comparative tests with the

most representative products from other firms in this sector.

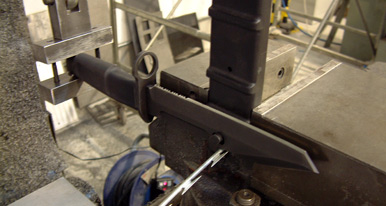

The capacity to

perforate is

measured by a machine of our own production, calibrated by an

electronic dynamometer on the average force applied by a man of medium

build.

The material used for this test is one or more NATO standard belts and

soft ballistic protection.

These tests have given interesting results regarding the

characteristics and the phenomenon connected with the perforation

capacity.

The same machine can be used for testing the blade efficency.

The falling tests

concern the robustness of the tips and tangs (for the bayonet we also

test the lug mechanism on the rifle).

The test involves dropping the knife from both positions from a

pre-established height inside a Plexiglas tube, which prevents the

knife from rotating without slowing the rapidity of its descent.

The flexibility and

resistance tests

are carried out using the electronic dynamometer which highlights the

load in kg on the product, fixed at both ends with opposing movement on

two different levels.

We calculate the limit of the elastic deformation and the breaking

point.

The oxidation tests are

carried out with the collaboration of the Florence University

of Engineering.

These tests comprise exposure to a saline fog in a controlled

atmosphere according to the time and percentage required by NATO

standards.

The electro miographic

test regarding ergonomics are made in collaboration with the Faculty

for Motor Sciences at Perugia University.

These tests take into consideration the pressures and possible

discomfort arising from a prolonged use of the blade as a work tool,

the hold and stability of the handle.

In case of accessories such

as the concertina wire cutter

on the bayonets we proceed by testing as vast as possible a range of

wires, until the product passes all of the possible tests.

|